Permalatt Vinyl Lattice vs. Big Box Store Lattice

What’s the difference?

In the beginning, lattice was made from wood slats and stapled together. Now there are two more options, vinyl, and plastic. We want to give you some information on the difference in Permalatt Products, Inc. solid core vinyl lattice and the plastic (HDPE) type lattice.

First though, you should know that there are a few things the two lattice options have in common. The common attributes are: both are rot resistant. Both are resistant to insects and the dreaded termite. Neither the vinyl nor the plastic lattice needs to be sealed to protect from moisture. Neither will peel. Those four things are where the commonalities stop.

Plastic lattice is made in an injection molding process with a wood grain pattern pressed/stamped on each side. Some say it mimics the look of real wood because of this process. The finished product is one continuous piece. Even if the plastic lattice has a 3-D look to it, it really is a solid piece of material. The plastic or HDPE lattice is readily available in the big box stores.

The plastic lattice is usually .15 inches thick but can be up to .25 inches. The sheets sizes available are 4’x 8’ and some stores offer 4’ x 4’. Being a continuous sheet, plastic lattice may expand and contract with temperature changes.

This means when installing the lattice you will need to leave a gap on all sides of the lattice for thermal movement. Without this gap, the lattice sheet could warp. The cold can also affect the integrity of the sheet. Cold temperatures can cause the sheet to crack and break at the places where it is nailed or screwed.

You may notice with this type of lattice that mold and mildew can grow on and in the textured surface. In order to keep it looking nice, you will need to clean it regularly. Therefore, it shouldn’t be said that plastic lattice is maintenance free.

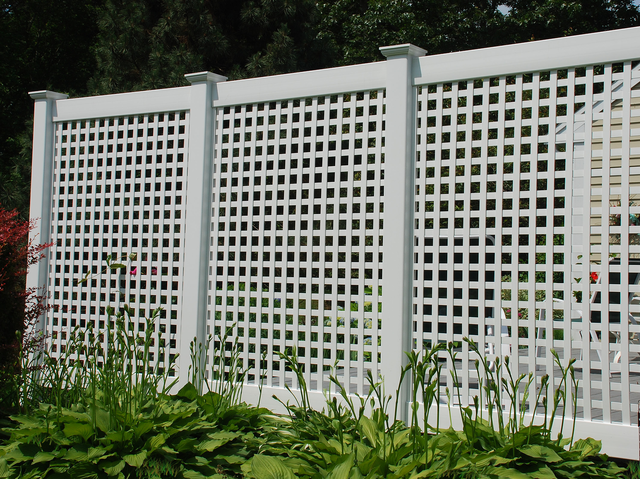

Permalatt Products, Inc. vinyl lattice is offered in two types of solid core vinyl. We manufacture the DuraShell® and the Decorative lattice products. Both lattice types are made strip over strip. All of our strips have a smooth surface.

The DuraShell® is a total thickness of ½” This total thickness is achieved where each of the ¼” thick strips cross in the pattern. DuraShell® also has a scuff and scratch resistant coating.

The Decorative lattice is a total thickness of ¼”. This total thickness is achieved where 1/8” thick strips cross each other in the pattern.

With the strip over strip construction, you will not have the expansion and contraction you see with a solid lattice sheet. The lattice sheet is dimensionally stable. For this reason, it will not warp. No need allow for additional room for our lattice sheet to expand.

You can easily nail or screw through the lattice and not be concerned with the possibility of damage where the lattice sheet is secured. Both of our lattice products will not become brittle, crack or splinter. Our lattice is mold and mildew resistant and yes, it’s maintenance free. If it gets dusty or dirty, simply spray it down with water, and you’re done.

We offer both the DuraShell® and Decorative lattice in standard sheet sizes of 4’ x 6’, 4’ x 8’, 12” x 6’ or 8’ and 16” x 6’ or 8’. We are capable of manufacturing custom sheet sizes for your convenience. We offer U-channel to frame or guide the sheet as well as an H-channel to connect sheets in your project.

DuraShell® and Decorative lattice is a niche product manufactured by Permalatt Products, Inc. and is not available in the big box stores. We manufacture a high quality premium vinyl lattice that is easy to cut and install. DuraShell® and Decorative lattice is “Made in the USA” by skilled craftspeople. Our propriety manufacturing process gives us a true 3-dimensional lattice that is truly 2nd to none.